Festo has launched an extensive new range of ultra-compact precision electric actuators that can be ordered and specified one day and delivered direct the next. This means that machine designers and builders can now take delivery of positioning actuators offering ±10 micron repeatability within 24 hours of placing their order. Downloadable PC-based software for dimensioning electromechanical linear axes and electric motors, backed by native CAD models of the actuators, further helps users accelerate design-in and machine build.

Festo has launched an extensive new range of ultra-compact precision electric actuators that can be ordered and specified one day and delivered direct the next. This means that machine designers and builders can now take delivery of positioning actuators offering ±10 micron repeatability within 24 hours of placing their order. Downloadable PC-based software for dimensioning electromechanical linear axes and electric motors, backed by native CAD models of the actuators, further helps users accelerate design-in and machine build.

Read more: Electroquip offers 24-hour delivery of new ultra-compact precision electric actuators

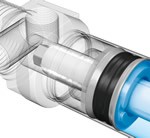

Festo has developed a unique self-adjusting pneumatic cushioning system, which is now available as a build to order option for the company's popular DSNU series round cylinder pneumatic actuators. The new system employs innovative, patented air channel geometry to provide phased venting of the cushioning air. The system automatically adapts its characteristics to suit the cylinder's prevailing load and speed conditions, to provide optimum end-position cushioning.

Festo has developed a unique self-adjusting pneumatic cushioning system, which is now available as a build to order option for the company's popular DSNU series round cylinder pneumatic actuators. The new system employs innovative, patented air channel geometry to provide phased venting of the cushioning air. The system automatically adapts its characteristics to suit the cylinder's prevailing load and speed conditions, to provide optimum end-position cushioning.

Festo is initially offering the new self-adjusting cushioning system on its popular DSNU family of round cylinders. Models available with the new system span diameters from 16 to 63 mm, with stroke lengths up to 500 mm – and delivery is usually within 24 hours.

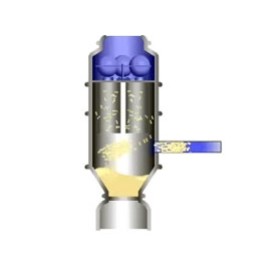

Why vacuum conveying?

Why vacuum conveying?

If we compare vacuum conveying with other methods such as a conveyor belt:

You minimize scrap as vacuum conveying is enclosed.

You lose a minimum of product as it cannot fall down off the sides.

One product will not contaminate another as the vacuum conveyor is very easy to clean.

Improved efficiency and reduced costs are amongst the main drivers in the packaging industry in 2010, according to PMMI. For manufacturers to achieve these goals, productivity and flexibility improvements are key.

Improved efficiency and reduced costs are amongst the main drivers in the packaging industry in 2010, according to PMMI. For manufacturers to achieve these goals, productivity and flexibility improvements are key.

Piab’s new piGRIP™ suction cup concept supports productivity-boosting efforts. It allows packaging lines to handle products at previously unprecedented speeds while also realizing cost and energy savings.

ABB's Compact range of panel switches, lamps, pushbuttons, E-stops and enclosures are now approved for the IP69K high-pressure, high-temperature washdowns.

ABB's Compact range of panel switches, lamps, pushbuttons, E-stops and enclosures are now approved for the IP69K high-pressure, high-temperature washdowns.

This rating provides waterproofing protection that exceeds NEMA 4X rating. This superior IP69K protection provides all the benefits of high pressure, high temperature washing: faster more complete sanitary cleaning with reduced waste.

Read more: IP 69k... New ratings are making a splash & great savings for you