Save Money - Reduce your 4th largest Energy Costs

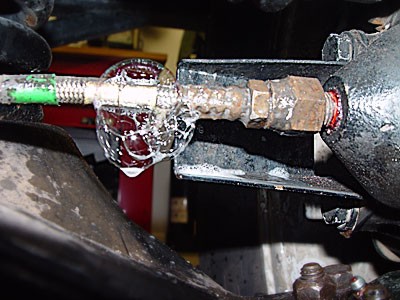

On average, 20% - 40% of compressed air is wasted, Save Money - Reduce your 4th largest energy costs by conducting an energy saving survey Some of our clients are now looking to reduce their energy costs, especially those related to the production and use of compressed air within the production environment. Our aim is to work closely with clients to provide them with an effective energy saving service and a bespoke program to ensure that the engineers become the cure rather than an additonal problem.

Some of our clients are now looking to reduce their energy costs, especially those related to the production and use of compressed air within the production environment. Our aim is to work closely with clients to provide them with an effective energy saving service and a bespoke program to ensure that the engineers become the cure rather than an additonal problem.

The Festo Energy Saving Survey is an excellent way of reducing your energy, maintenance, logistics & machine downtime costs.

The aim of these surveys is to increase productivity by reducing production costs. On average, 20% - 40% of compressed air is wasted.

The industry yardstick for this cost is 1.5p/m³.

What do these leakages cost?

Leakage Ø / mm Volume / m³ per year Cost per year

0.5 7,709 £115

1 38,500 £580

1.5 65,700 £980

2 136,600 £2,050

3 307,500 £4,600

4 546,600 £8,200

bigger more even more

Electroquip Ltd and Festo would address the problem from both a reactive approach and a proactive approach.

Reactive Approach

Carry out a Festo Energy Saving Survey to find out what the specific issues are and to identify the root cause of these problems.

What is the current air use and leakage rate?

What applications are high users?

What safety concerns can be found?

What improvements can be made?

Proactive Approach

Increase the skill and knowledge levels of the engineers to stop these issues re-entering the production environment and make design improvements. Any future decision has to consider:

Tools

Attitude

Skill

Knowledge

If you would like further information on the Festo Energy Saving Survey, please contact us directly at Electroquip