Festo Semi-Rotary Actuators: Optimizing Precision and Performance for Industrial Applications

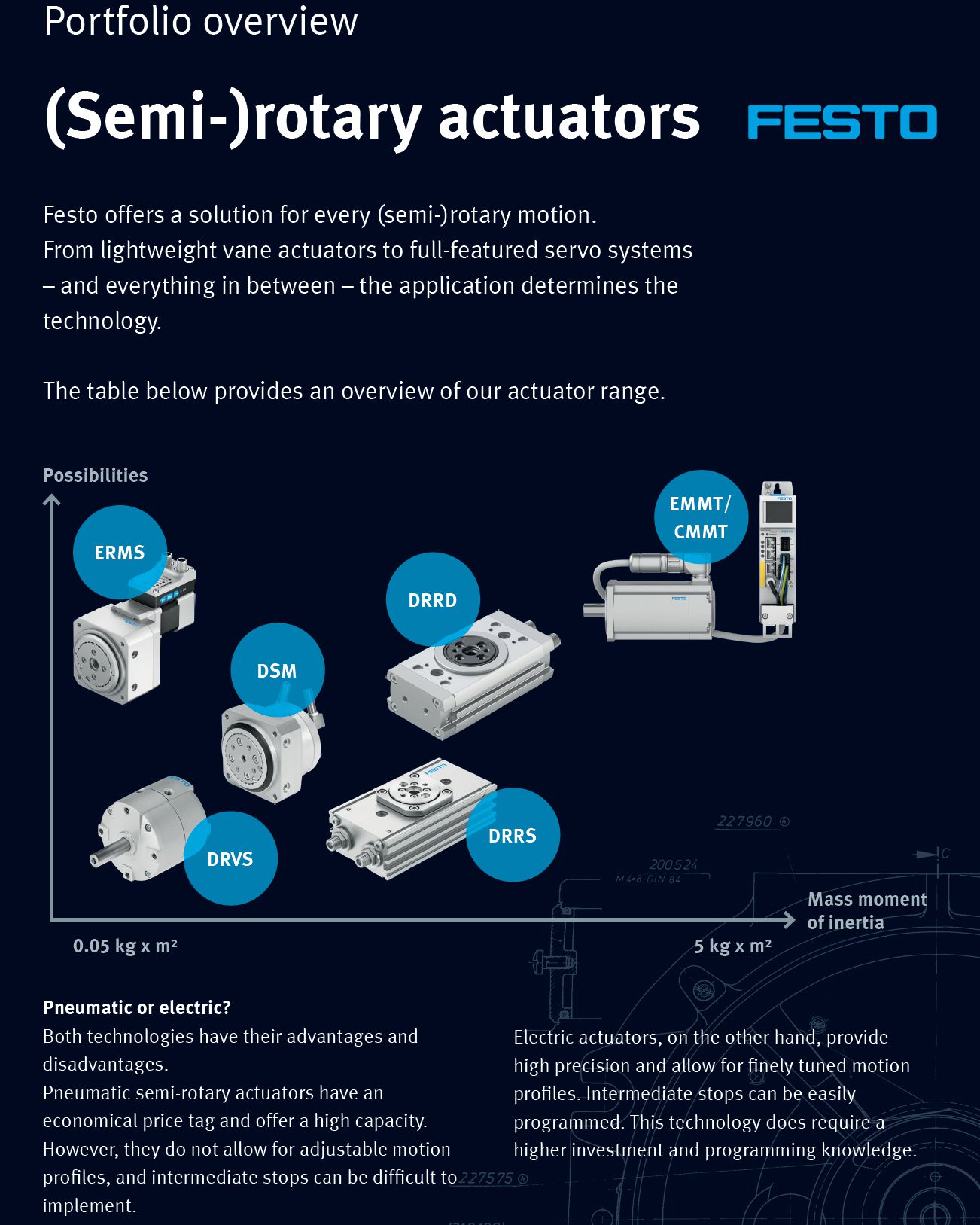

In today's fast-paced industrial environments, automation and precision are paramount. Festo, a leading global provider of automation technology, offers a rang e of semi-rotary actuators designed to meet the demands of various industrial applications. With models like ERMS, DRVS, DRRS, DRRD, EMMT/CMMT, DSM, and DHTG, Festo provides cutting-edge solutions for reliable and high-performance motion control.

e of semi-rotary actuators designed to meet the demands of various industrial applications. With models like ERMS, DRVS, DRRS, DRRD, EMMT/CMMT, DSM, and DHTG, Festo provides cutting-edge solutions for reliable and high-performance motion control.

In this article, we will explore the features, benefits, and applications of these semi-rotary actuators, explaining why they are an essential part of any automation system.

What Are Semi-Rotary Actuators?

Semi-rotary actuators are devices that generate rotational motion in a limited range, typically up to 180° or 360°. They are used to convert compressed air or electrical energy into precise, controlled rotary motion. Unlike traditional rotary actuators, semi-rotary actuators are often more compact, cost-effective, and simpler to integrate into various mechanical systems.

Festo’s range of semi-rotary actuators offers flexibility, efficiency, and accuracy, making them ideal for applications like valve control, positioning, clamping, and more.

Key Models in the Festo Semi-Rotary Actuator Range

- ERMS (Electric Rotary Motor System)

Features:

- Electric drive: The ERMS is an electric rotary actuator designed for dynamic applications.

- Flexible mounting options: Can be mounted in various orientations to fit different machine configurations.

- Compact design: Saves space and ensures easy integration.

- Precise control: Offers high positioning accuracy and repeatability.

Benefits:

- Ideal for automation systems that require precise rotary motion control.

- Reduces energy consumption compared to pneumatic actuators.

- Provides excellent control over speed and torque, making it perfect for applications requiring high-performance and accuracy.

- DRVS (Pneumatic Rotary Actuator)

Features:

- Robust construction: Made of high-quality materials to withstand tough environments.

- Rotary movement with adjustable angle: Available with 90° or 180° rotation.

- Integrated cushioning: To avoid abrupt stops and reduce wear and tear.

Benefits:

- Perfect for applications requiring high torque and precision.

- Cost-effective solution with low maintenance needs.

- Reliable performance, even in demanding industrial conditions.

- DRRS (Pneumatic Rotary Actuator with Rotation Sensor)

Features:

- Built-in rotation sensor: Provides feedback on angular position, enabling precise control.

- Compact design: Saves space and simplifies integration.

- Available in multiple sizes: Suited for various torque requirements.

Benefits:

- The addition of a rotation sensor enhances precision and monitoring.

- Enables automated feedback systems for more accurate process control.

- Versatile and flexible, ideal for a wide range of industrial automation systems.

- DRRD (Double Rotary Actuator)

Features:

- Dual rotation: Offers two independent rotation outputs in a single actuator.

- Simultaneous or sequential operation: Provides versatility in motion control.

- Adjustable angle of rotation: Allows for customizable performance based on application needs.

Benefits:

- Saves space by combining two actuators into one.

- Cost-effective, reducing both material and installation costs.

- Perfect for applications where two different movements need to be synchronized or executed independently.

- EMMT / CMMT (Electric Motion Systems)

Features:

- Highly dynamic performance: EMMT and CMMT systems provide exceptional speed and acceleration.

- Energy-efficient: Advanced control algorithms reduce energy consumption.

- Modular design: Flexibly integrates into different automation systems.

- Compact, robust, and precise: High quality and performance in a small form factor.

Benefits:

- Suitable for high-precision applications where speed and torque are critical.

- Energy-efficient operation helps to reduce operational costs.

- Flexible integration into both new and existing automation systems.

- DSM (Rotary Motor with Magnetic Coupling)

Features:

- Magnetic coupling: Prevents mechanical wear and tear by using magnets for the coupling mechanism.

- Easy installation: The actuator is designed to be easily integrated into existing systems.

- Long lifespan: Reduced wear and tear increase the overall service life of the actuator.

Benefits:

- Perfect for environments where mechanical wear is a concern.

- Reduces maintenance costs and downtime.

- Offers superior precision and reliability in rotating applications.

- DHTG (Heavy-Duty Rotary Actuator)

Features:

- High torque output: The DHTG actuator is designed for applications requiring significant rotary force.

- Durable and rugged construction: Withstands heavy-duty environments.

- Rotational speed control: Offers flexibility in adjusting the speed of operation.

Benefits:

- Ideal for applications with heavy loads and high torque requirements.

- Reliable performance in harsh industrial environments.

- Long-lasting durability, ensuring minimal maintenance and reduced downtime.

Why Choose Festo Semi-Rotary Actuators?

- High Precision and Control

Festo's semi-rotary actuators provide exceptional control over rotational motion. This precision is vital in industries such as automotive, packaging, and manufacturing, where accuracy and repeatability are crucial.

- Energy Efficiency

Whether you're using pneumatic or electric actuators, Festo has designed its systems to minimize energy consumption while maximizing performance. This leads to reduced operational costs and a more sustainable manufacturing process.

- Versatile Applications

From valve control to robotic arms, Festo’s actuators are built to handle a wide range of industrial applications. With various configurations and sizes, there’s a solution for almost every need.

- Reliability and Durability

Festo products are renowned for their reliability. Built to withstand demanding industrial environments, these actuators are designed to operate smoothly with minimal maintenance, extending their service life.

- Easy Integration

Festo's actuators are engineered for easy integration into existing automation systems. Whether you’re retrofitting an older machine or building a new production line, these actuators can be seamlessly incorporated into your setup.

Conclusion

Festo’s semi-rotary actuators, including models like ERMS, DRVS, DRRS, DRRD, EMMT/CMMT, DSM, and DHTG, offer a range of high-quality, reliable, and precise solutions for industrial automation. These actuators provide numerous benefits, including energy efficiency, versatility, durability, and ease of integration. Whether you need pneumatic or electric actuation, Festo’s range ensures that your system operates smoothly and efficiently, reducing both operational costs and downtime.

If you’re looking to optimize your automation processes with cutting-edge motion control solutions, Festo’s semi-rotary actuators are the perfect choice for your business. Explore our range today and experience the power of precision engineering at Electroquip, No.1 for Festo from UK stock.

Call to Action

Ready to enhance your automation system with Festo’s semi-rotary actuators? Contact us today at Electroquip to learn more about how our range of actuators can improve your process efficiency, precision, and overall productivity.