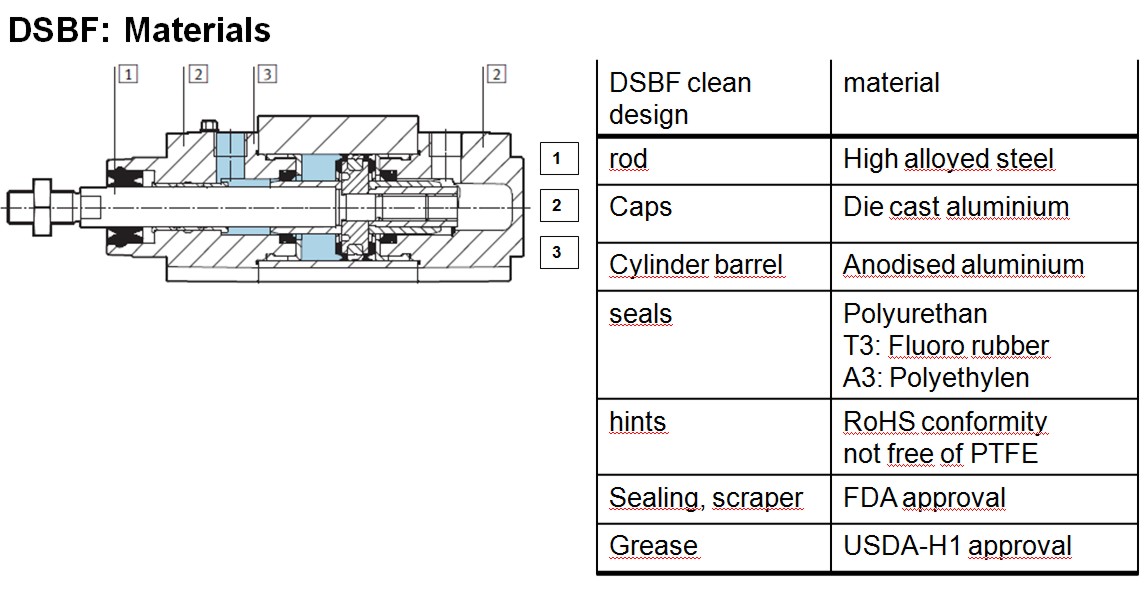

Festo Clean Up - With their new range Market Leading Clean Design Cylinders IP67/68 Sensor option

New range of cylinders setting a bench mark for the Food Berverage

New range of cylinders setting a bench mark for the Food Berverage

and packaging markerts - DSBF standard range of Clean Design pneumatic cylinders

Highlights of the Festo DSBF cylinders

•Clean design no edges or grooves; water can flow off

•Self-adjustable PPS cushioning convenient and clean

•FDA and USDA-H1 approval - needed for F&B

•A3 option for un-lubricated operation needed when grease is washed off

•Many options like T1, T3 for individual applications

•Rail for clean design sensor SMT-C1

•Price flexibility - thanks to new design concept

Festo DSBF Cylinder: Optional features - new configuration part numubers electroquip can help your selection

The new cylinders are currently avaiable from Electroquip on a 5 working days delivery as standard and express

build option is available by specail request - enquire

Temperature range: Standard

T1 for heat resistant sealing max. 120 °C

T3 for temperature range -40 … + 80 °C

(low temperature resistance)

Scraper: none

A3 for un-lubricated operation

Rod type: one piston rod

T Through piston rod K8 extended rod

Piston rod thread: male threat

F female thread

Rod thread extension:

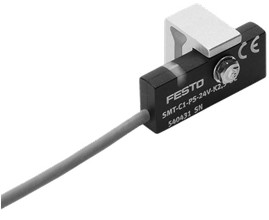

Sensor mounting: R rail for external sensors New IP65 & IP68 Senosor for the clean design range of cylinders

New IP65 & IP68 Senosor for the clean design range of cylinders

IP 65/68 and easy-to-clean

SMT-C1 -

•for the F&B cylinders DGRF, CDC and DSBF

•The SMT-C1 is the standard cylinder sensor for the F&B sector.

• It has an easy-to-clean design and is rugged

•New longer cable variants and newly introduced plug types cover all food industry requirements as indicated by current surveys.

• attractive project prices possible

Please contact us at Electroquip to help with your Clean Design Cylinder requirements