Festo Pneumatics > Festo Electric Drives and Cylinders with Rapid Delivery

Festo Electric Drives > Festo Electric Drives and Cylinders with Rapid Delivery from long serving Festo Distributor Electroquip

Festo Electric Drives > Festo Electric Drives and Cylinders with Rapid Delivery from long serving Festo Distributor Electroquip

Festo Pneumatics are able to provide electric components far quicker than their competitors as they are capable of delivering 95% of their electrical drive components in under a week. Even changing suppliers is easier with a little know how and help from Electroquip Festo Pneumatics due to their Positioning Drives, as their free sizing and simulation software can meet customer’s requirements in a few minutes.

As motion control is used more and more in industry, logistics are increasingly becoming more vital. Festo Pneumatics have recognised this and therefore now offer 58 types of motor, 24 types of controller and 22 types of gearbox which are readily available for next day delivery. Due to this large amount of stock it allows customers flexibility in their designs and convenience in your supply.

Festo Pneumatics make sure that application flexibility is top priority with their customers. Therefore providing items such as safe lead screws, precise ball screws and dynamic linear motors. There are also 42 various types of electrical cylinders available in stock. If you merge these items with Festo’s motor drives and axial kits for an entire electrical drive motion system for next day delivery. Festo Pneumatics also provide high precision, dynamic linear motors on only 7 days delivery.

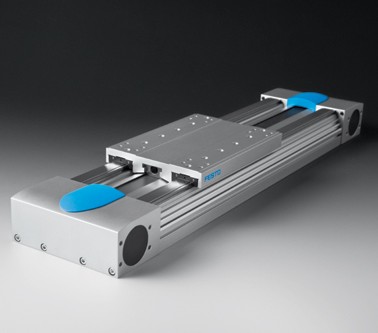

If an electrical axis needs to be designed to your specifications then these cannot be held in stock, however the quick and convenient online tools means that these can be produced up to 8.5 metres long, in only 7-10 days. Festo’s EGC axis provides high rigidity, dynamic motion and robust bearing systems in a much shorter delivery time than most bearing systems alone.

If you need extreme rigidity and repeatability better than 0.01mm you might think that the lead times would be weeks if not months. Due to Festo Pneumatics award winning supply chain you could obtain over 35 different sizes of precision guided ball screws next day. The Festo EGSK selection of axis offers load ratings of over 45,000 N and speeds of 0.5m/s in a small package with matching motors and mountings from stock.

Where minimum functionality but maximum performance is needed then the ELGR belt axis contains exactly what you need whilst being value for money. The axis is the perfect alternative to manufacturing belt drives in house with the advantages of assured performance, lifetime and configuration online. At a class leading 7-10 days delivery for any size stroke, the axis provides security that a complete axis can be obtained even faster than trying to design and produce a drive yourself.

Type Size Nominal stroke(mm) Repetition accuracy(mm) Max. feed force(N)

Festo Toothed belt axis - EGC-TB-KF 50 ,70, 80, 120, 185 10,000 ±0,08 mm 50 ... 2,000

Description : High speeds and feed forces, Maximum rigidity, High loads and torques, Min distance guide centre and a Choice of motor assembly

Festo Spindle axis - EGC-BS-KF 70, 80, 120, 185 100 ... 3,000 ±0,02 mm 300 ... 3,000

High speeds and feed forces, Maximum rigidity, High loads and torques, Minimum distance between load and guide centre and Choice of motor assembly

Festo Electric cylinder DNCE 32 ... 63 1 ... 800 ±0.02 ... 0.07 300 ... 1,625

Lead screw or ball screw, Standard hole pattern to ISO15552, Axial or parallel motor interface and Non-rotating piston rod

Festo Toothed belt axis DGE-ZR 8 ... 63 1 ... 4,500 ± 0.08 ... 0.1 15 ... 1,500

Electro-mechanical axis with toothed belt

Festo Toothed belt axis DGE-ZR-KF 8 ... 63 1 ... 4,500 ± 0.08 ... 0.1 15 ... 1,500

Electro-mechanical axis with toothed belt and recirculating ball bearing guide

Festo Toothed belt axis DGE-...-ZR-HD 18, 25, 40 1 ... 4,000 ± 0.08 ... 0.1 60 ... 610

Electro-mechanical axis with heavy-duty guide

Festo Toothed belt axis DGE-...-ZR-RF 25, 40, 63 1 ... 5,000 ± 0.1 260 ... 1,500

Electro-mechanical axis with toothed belt and internal roller bearing guide

Festo Cantilever axis DGEA-...-ZR-KF 18, 25, 40 1 ... 1,000 ± 0.05 230 ... 1,000

Electro-mechanical axis with toothed belt and recirculating ball bearing guide

Festo Spindle axis DGE-SP 18 ... 63 1 ... 1,500 ± 0.02 140 ... 1,600

Festo Pneumatics range of Electro-mechanical axis with spindle drive

Festo Spindle axis DGE-...-SP-KF 18 ... 63 1 ... 2,000 ± 0.02 140 ... 1,600

Festo Pneumatics range of Electro-mechanical axis with spindle drive and recirculating ball bearing guide

Festo Spindle axis DGE-...-SP-HD 18, 25, 40 1 ... 1,500 ± 0.02 140 ... 600

Festo Pneumatics range of Electro-mechanical axis with spindle drive and heavy-duty guide

Festo Positioning servo axis DMES-...-GF 18 ... 63 1 ... 1,800 ± 0.05 240 ... 3,000

Festo Pneumatics range of Mechanical linear drive with trapezoidal spindle and plain-bearing guide

Festo Positioning servo axis DMES-...-KF 18 ... 63 1 ... 1,800 ± 0.05 240 ... 3,000

Festo Pneumatics range of Mechanical linear drive with trapezoidal spindle and recirculating ball bearing guide

Festo Handling axis HME 16, 25 300, 400 ± 0.03 175, 235

Festo Pneumatics range of Electric linear module with linear motor and recirculating ball bearing guide

Festo Mini slide SLTE 10, 16 80, 150 ± 0.05 ± 0.055 10, 30

Trapezoidal spindle and recirculating ball bearing guide, Constant and precise speed, DC servo motor, I/O connection and Profibus connection

Quick delivery is not the only aspect of electrical drives that can provide both security and convenience. By using Festo Pneumatics Positioning drives software it means that you are able to size your application to gain quick calculations for axis, bearings and drives. This can be downloaded from Festo’s website for free! The software means that calculations that would otherwise take hours can be in front of you in a matter of minutes. This minimises both documentation time and costs.

Require help selecting the right drive for your application please call us at Electroquip we are only to happy to guide you through you Festo Pneumatics drive selection.