Festo Vacuum Products: Advanced Solutions for Efficient Automation and Handling

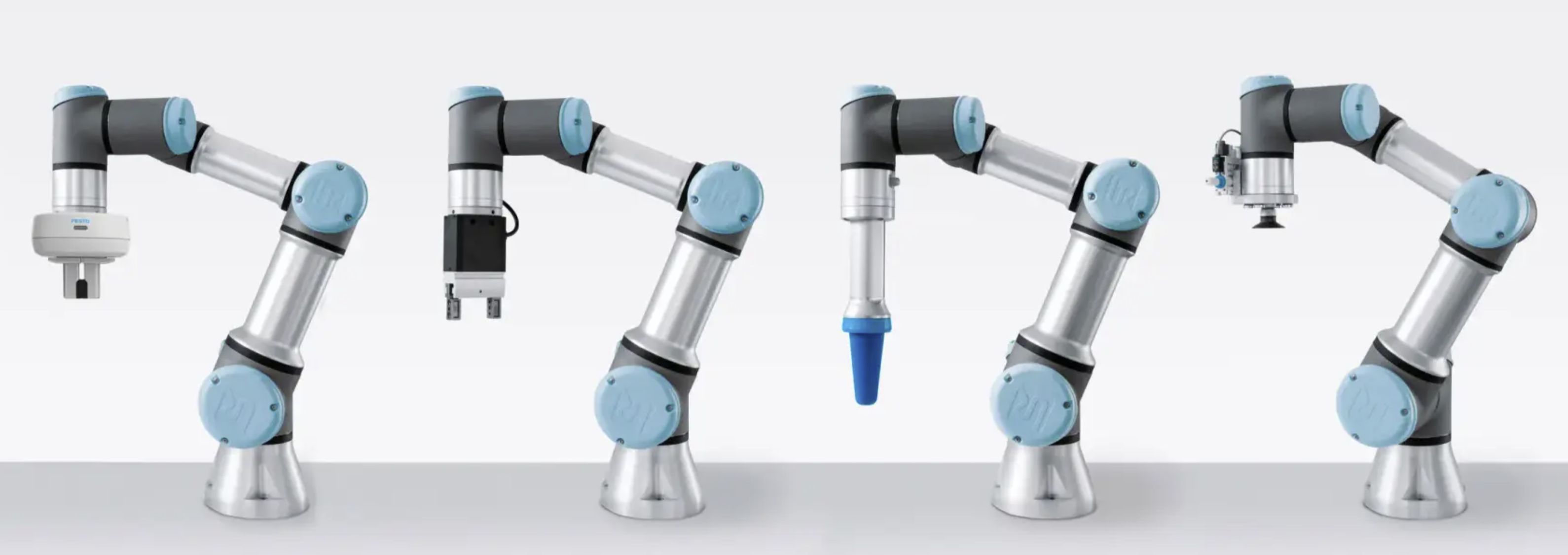

In the world of industrial automation, precision, efficiency, and reliability are key to success. Festo, a global leader in automation technology, offers an extensive range of vacuum products designed to optimize performance across various industrial applications. With solutions that span across vacuum generators, vacuum pumps, grippers, and valves, Festo provides cutting-edge products that enhance productivity, reduce energy consumption, and ensure flawless handling in diverse environments.

In the world of industrial automation, precision, efficiency, and reliability are key to success. Festo, a global leader in automation technology, offers an extensive range of vacuum products designed to optimize performance across various industrial applications. With solutions that span across vacuum generators, vacuum pumps, grippers, and valves, Festo provides cutting-edge products that enhance productivity, reduce energy consumption, and ensure flawless handling in diverse environments.

This article explores the Festo vacuum product range, highlighting key products, their features, and benefits to help you understand why Festo’s solutions are ideal for your business needs.

Why Festo Vacuum Products Are Essential for Your Operations

Vacuum technology plays a crucial role in industrial automation, especially in tasks like lifting, positioning, and gripping. Festo’s vacuum systems are engineered to improve efficiency, minimize energy usage, and provide precise control, making them an indispensable part of modern manufacturing and material handling.

Festo Vacuum Product Range: Key Offerings

- Vacuum Generators (OVEM, OVGF, and OVZR Series)

Features:

- Compact and powerful: These vacuum generators are designed to be small in size but high in performance, making them ideal for applications where space is limited.

- Low energy consumption: Festo’s vacuum generators are engineered to minimize energy use while delivering strong vacuum power.

- Quick response time: Ensures rapid handling for increased production speeds.

- Integrated silencer: Reduced noise for a quieter working environment.

- Multiple configurations: Available in various sizes and types, including ejector systems and multistage versions, for versatile applications.

Benefits:

- Energy efficiency: Festo’s vacuum generators are designed to consume minimal energy, lowering operational costs.

- Space-saving design: The compact size of the generators ensures they can be integrated into even the tightest spaces without compromising performance.

- Reduced noise: Integrated silencers improve the work environment by minimizing noise levels.

Applications:

- Ideal for handling delicate materials in industries like packaging, food, and electronics.

- Vacuum Pumps (DVP, DLS, and VFF Series)

Features:

- Robust performance: Festo’s vacuum pumps are built to handle a variety of tasks, providing consistent performance even in tough conditions.

- Oil-free operation: Many of Festo's pumps are designed for oil-free operation, making them ideal for clean environments.

- Quiet operation: Designed with sound-absorbing materials for quieter operation.

- High reliability: With low maintenance requirements, Festo vacuum pumps offer long service life.

- Varied configurations: Available in both dry and wet types for different industrial needs.

Benefits:

- Durability: Built for long-lasting performance in demanding industrial applications.

- Cost-effective: Reduced maintenance and energy consumption result in lower overall operational costs.

- Clean operation: Oil-free vacuum pumps ensure that your workspace remains clean and free from contaminants.

Applications:

- Perfect for environments like medical or food processing industries where contamination control is critical.

- Vacuum Grippers (VAD, VAGF, and VGC Series)

Features:

- Versatile and adaptable: Festo vacuum grippers offer various shapes and sizes, providing flexibility in handling objects of different sizes and materials.

- Integrated sensors: Many vacuum grippers come with sensors that detect object position and ensure precise gripping.

- Customizable designs: Festo offers customizable vacuum grippers to suit specific handling tasks.

- Energy-efficient operation: Designed for minimal air consumption and maximum gripping force.

Benefits:

- Increased productivity: The quick and secure gripping of items reduces cycle times and enhances overall system efficiency.

- Minimized risk of damage: Festo's grippers are gentle on sensitive items, ensuring minimal risk of damage during handling.

- Higher precision: Integrated sensors and adjustable suction ensure that objects are handled precisely and securely.

Applications:

- Perfect for assembly lines, pick-and-place operations, and material handling in industries such as automotive, electronics, and packaging.

- Vacuum Valves (VZWF, VZFA, and VZNS Series)

Features:

- High-performance control: These vacuum valves provide efficient control of vacuum pressure, ensuring reliable operation.

- Modular design: Designed to be easily integrated into various vacuum systems with flexible mounting options.

- Durability: Made from high-quality materials, Festo's vacuum valves are resistant to wear and tear, ensuring a long lifespan.

- Compact size: These valves are designed to take up minimal space while offering high performance.

- Quick response: Ensures fast vacuum switching times, crucial for high-speed automation.

Benefits:

- Improved system reliability: Ensures precise control and consistent vacuum levels for efficient operation.

- Energy efficiency: By optimizing the vacuum cycle, these valves help reduce energy consumption across your vacuum system.

- Reduced downtime: With a robust and reliable design, these valves reduce the risk of system failure and maintenance issues.

Applications:

- Ideal for use in industrial automation systems where precise vacuum control is necessary, such as material handling and robotics.

- Vacuum Switches and Sensors (VSM, VSE, and VXS Series)

Features:

- Accurate vacuum detection: Festo’s vacuum switches and sensors provide accurate feedback on vacuum levels, ensuring system reliability.

- Versatile mounting: Easy to mount in various locations within the system.

- User-friendly interface: Provides intuitive controls for adjusting vacuum levels and settings.

- Built-in diagnostics: Many of these products include diagnostic features that allow for easy monitoring and troubleshooting.

Benefits:

- Enhanced control: Real-time feedback ensures that vacuum levels are maintained precisely, preventing errors in operation.

- Improved system efficiency: By continuously monitoring the vacuum pressure, these sensors help optimize system performance.

- Reduced downtime: Built-in diagnostic features allow for proactive maintenance, minimizing potential downtime.

Applications:

- Ideal for vacuum systems used in packaging, robotics, and assembly processes where real-time feedback is essential.

Why Choose Festo Vacuum Products?

- Industry-Leading Technology

Festo’s vacuum products incorporate advanced technology to ensure the highest levels of performance, energy efficiency, and reliability. With a reputation for cutting-edge engineering, Festo provides vacuum solutions that help businesses stay ahead in competitive industries.

- Comprehensive Range

Whether you're looking for vacuum generators, pumps, grippers, or valves, Festo offers a wide range of vacuum products to meet your specific requirements. With flexible configurations and a variety of sizes, these solutions cater to industries as diverse as automotive, food processing, electronics, and packaging.

- Energy Efficiency

Energy savings are a top priority in today’s manufacturing landscape. Festo’s vacuum products are designed to minimize energy consumption, reduce costs, and promote sustainable operations.

- Reliable Performance

With rigorous quality control standards and durable construction, Festo vacuum products are built to last, even in the most demanding environments. Their reliability ensures that your operations run smoothly with minimal downtime.

- Easy Integration

Festo products are engineered to integrate seamlessly into a variety of automation systems. Their modular designs make installation quick and easy, so you can get your vacuum system up and running with minimal disruption.

Conclusion

Festo’s vacuum product range offers a comprehensive suite of high-quality, energy-efficient solutions that meet the demands of modern industrial automation. From vacuum generators and pumps to grippers and valves, Festo’s vacuum systems are designed to optimize performance, reduce energy consumption, and enhance the efficiency of your operations.

By incorporating Festo’s vacuum products into your automation processes, you can expect reliable performance, reduced maintenance costs, and a boost in productivity.

Call to Action

Ready to optimize your automation systems with Festo’s vacuum products? Contact us today at Electroquip your 1st call for the complete range of Festo product to learn more about how our vacuum solutions can improve your operations and enhance your productivity.