Free Festo Energy Efficiency on-site report available to UK Manufacturers

Electroquip have teamed up with Festo to offer UK manufacturing a comprehensive range of serives to monitor energy efficiency and combat air wastage

Electroquip have teamed up with Festo to offer UK manufacturing a comprehensive range of serives to monitor energy efficiency and combat air wastage

On Average 25% – 35% of compressed air is wasted

24 hours per day, 365 days per year

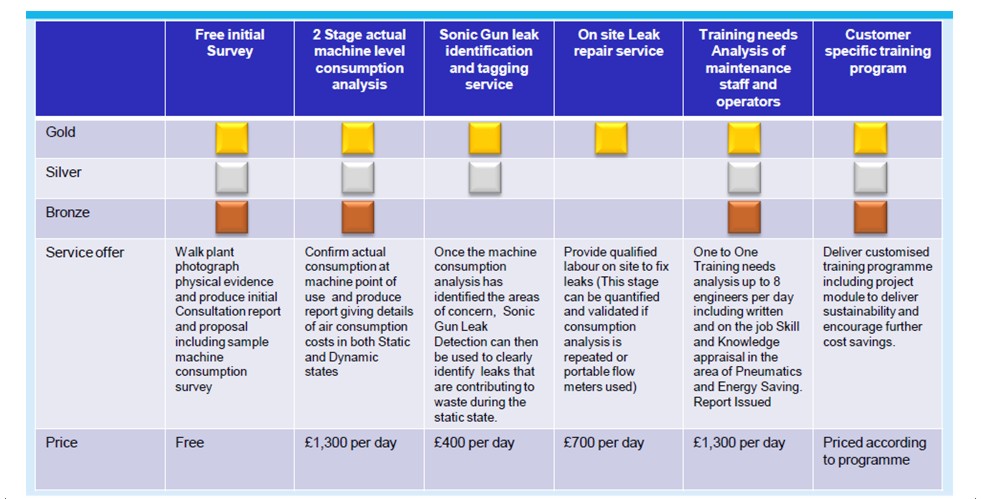

Why talk to Festo & Electroquip?

Electroquip have the sales force in order to deliver the relevant information to you in the time frames you need and to co-oridate and guide you through the total Energy Efficiency product offerings. Where as Festo is not just a supplier or a manufacturer - we experienece the same problems as you do.

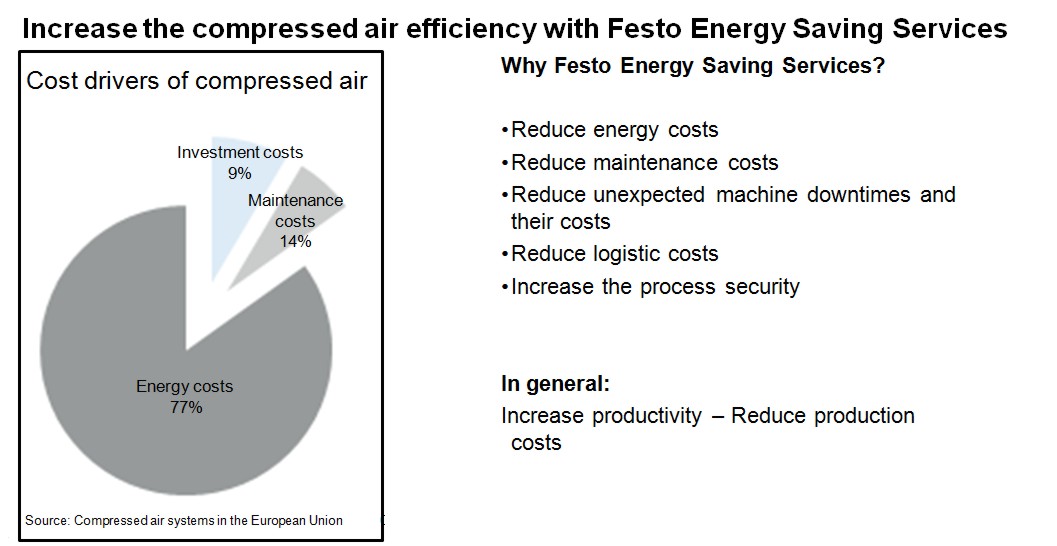

There are five major energy savings measures in compressed air systems:-

42% Detection and reduction of leakages

26% Other activities

12% Pneumatic system design including multi pressure pipe network

10% Heat recovery

10% Adjustable speed motor compressors

Source: Compressed air systems in the European Union, ISI 2000

Leakage control is an educational & logistical problem, not a detection problem

Contact us at Electroquip for a free of charge no obligation Energy Efficiancy summary on a part of your Manufacturing plant today in order to summerise how much money you can save by implamenting a standard or taylor made plan to meet your needs