Why vacuum conveying?

Why vacuum conveying?

If we compare vacuum conveying with other methods such as a conveyor belt:

You minimize scrap as vacuum conveying is enclosed.

You lose a minimum of product as it cannot fall down off the sides.

One product will not contaminate another as the vacuum conveyor is very easy to clean.

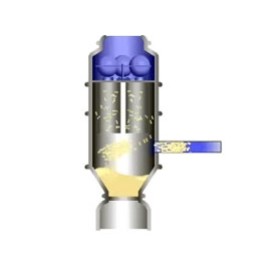

Vacuum is used with great advantage in order to convey dry powder products through dedicated pipe systems. PIAB's vacuum conveying systems are built of strong components of high quality. Our objective is to offer solutions that help our customers raise their productivity.

Production of food, pharmaceuticals and chemical products demands the highest possible degree of safety as to hygiene and operation. Piab's C series of vacuum conveyors has been developed as an answer to the severe requirements of operational safety and hygiene in the food, pharmaceutical and chemical industries.

PIAB Modular conveyors – C series

The C series has been developed to meet the demands mainly in the food and chemical industries. With the modular vacuum conveyor you can adjust your conveyor according to your needs and demands. The modular conveyor has a hygienic design. It is made of ASTM 316L steel and the surface on the modules is at least Ra 0.8. There are several ...

PIAB Unibody conveyors – UC series

The UC conveyors are designed for customers with high needs of a vacuum conveyor with high hygienic standard, as the pharmaceutical and food industry. To make it easier to clean and to validate the cleaning process, the body of the conveyor is made in one piece and has no joints in the product contact zone. It is made of ASTM 316L steel ...

PIAB Industrial conveyors – IC series

The IC series has been developed to meet the demands of the manufacturing industry. Some examples of its applications are conveying of plastic powders and granules, ceramic powder, metal powder, colouring pigment, powder for water purification, saw dust and materials used in the manufacture of tyres. The maximum material conveying ...

PIAB ATEX conveyors

Since there are special safety requirements for equipment and health protection for workers in potentially explosive atmospheres the EU has created legislation for this called the ATEX directives. (ATEX is an abbreviation for Atmosphère Explosible). Equipment that is certified according to the ATEX directive 94/9/EC has to be designed in ...

PIAB USDA conveyors

USDA and 3-A accepted conveyors that meet the stringent sanitary requirements of the food, dairy and pharmaceutical industries. The USDA conveyor follows the regulation of USDA guideline for hygienic design. It is made of ASTM 316L steel and the surface is at least Ra 0.8. The conveyor has an external filter shock to clean the filter ...

Spare parts

The vacuum conveyor is reliable and requires a minimum of maintenance. It is, however, necessary to regularly change some of the parts to maintain maximum productivity.

Please contact us at Electroquip to discuss your convaying ideas in more detail