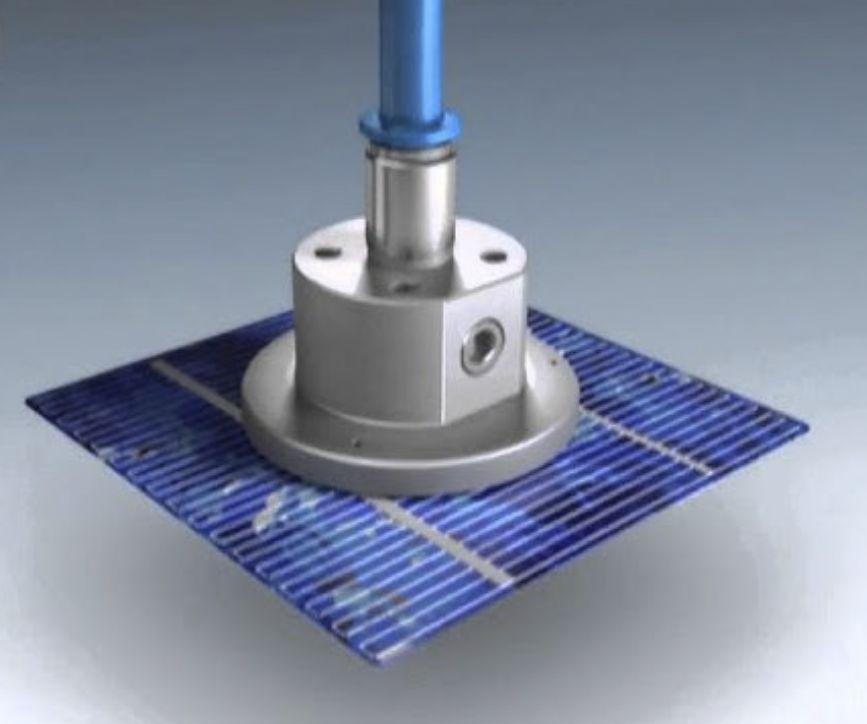

Festo Bernoulli Gripper OGGB: Non-Contact Precision Handling

The Festo Bernoulli Gripper OGGB offers innovative, non-contact gripping technology that ensures high-precision handling of delicate and lightweight objects.

Using airflow technology based on the Bernoulli principle, this gripper creates a stable vacuum to pick up and hold components without physical contact, minimizing the risk of damage.

Ideal for industries like electronics, pharmaceuticals, and packaging, the OGGB provides a reliable, energy-efficient solution for modern automation systems. Full Festo product range available from Electroquip, your 1st call For Festo Products.

Read more: Festo OGGB Gripper Precision Handling | Bernoulli Gripper

Festo Vacuum Products: Advanced Solutions for Efficient Automation and Handling

In the world of industrial automation, precision, efficiency, and reliability are key to success. Festo, a global leader in automation technology, offers an extensive range of vacuum products designed to optimize performance across various industrial applications. With solutions that span across vacuum generators, vacuum pumps, grippers, and valves, Festo provides cutting-edge products that enhance productivity, reduce energy consumption, and ensure flawless handling in diverse environments.

In the world of industrial automation, precision, efficiency, and reliability are key to success. Festo, a global leader in automation technology, offers an extensive range of vacuum products designed to optimize performance across various industrial applications. With solutions that span across vacuum generators, vacuum pumps, grippers, and valves, Festo provides cutting-edge products that enhance productivity, reduce energy consumption, and ensure flawless handling in diverse environments.

This article explores the Festo vacuum product range, highlighting key products, their features, and benefits to help you understand why Festo’s solutions are ideal for your business needs.

Why Festo Vacuum Products Are Essential for Your Operations

Vacuum technology plays a crucial role in industrial automation, especially in tasks like lifting, positioning, and gripping. Festo’s vacuum systems are engineered to improve efficiency, minimize energy usage, and provide precise control, making them an indispensable part of modern manufacturing and material handling.

Read more: Festo Vacuum Product - Getting to Grips Latest Solutions

Festo Semi-Rotary Actuators: Optimizing Precision and Performance for Industrial Applications

In today's fast-paced industrial environments, automation and precision are paramount. Festo, a leading global provider of automation technology, offers a rang e of semi-rotary actuators designed to meet the demands of various industrial applications. With models like ERMS, DRVS, DRRS, DRRD, EMMT/CMMT, DSM, and DHTG, Festo provides cutting-edge solutions for reliable and high-performance motion control.

e of semi-rotary actuators designed to meet the demands of various industrial applications. With models like ERMS, DRVS, DRRS, DRRD, EMMT/CMMT, DSM, and DHTG, Festo provides cutting-edge solutions for reliable and high-performance motion control.

In this article, we will explore the features, benefits, and applications of these semi-rotary actuators, explaining why they are an essential part of any automation system.

What Are Semi-Rotary Actuators?

Semi-rotary actuators are devices that generate rotational motion in a limited range, typically up to 180° or 360°. They are used to convert compressed air or electrical energy into precise, controlled rotary motion. Unlike traditional rotary actuators, semi-rotary actuators are often more compact, cost-effective, and simpler to integrate into various mechanical systems.

Festo’s range of semi-rotary actuators offers flexibility, efficiency, and accuracy, making them ideal for applications like valve control, positioning, clamping, and more.

New Festo SFAM Next Generation Range of Flow Sensors -

One flow sensor for everything.

The built-in pressure sensor and temperature measurement offer a wide range of options for process

monitoring and control. In addition, by eliminating the need for an additional pressure sensor the

installation effort and costs can be minimised. The ability to measure the gases Ar, N2,and C02 also

allows you to monitor inert gas applications.

New with IO-Link® communication

All measurement data can be transferred to the controller via the IO-Link® interface. The advantages

are minimal wiring effort, convenient remote parameterisation and a cost-effective, standardised

connecting cable.

Maximum flexibility for maximum cost efficiency

PNP or NPN? NO or NC? 0 … 10 V, 1 … 5 V or 4 … 20 mA? The SFAM can do everything in one device.

The electrical outputs can be switched using software. This also simplifies storage, reduces costs and

provides greater flexibility.

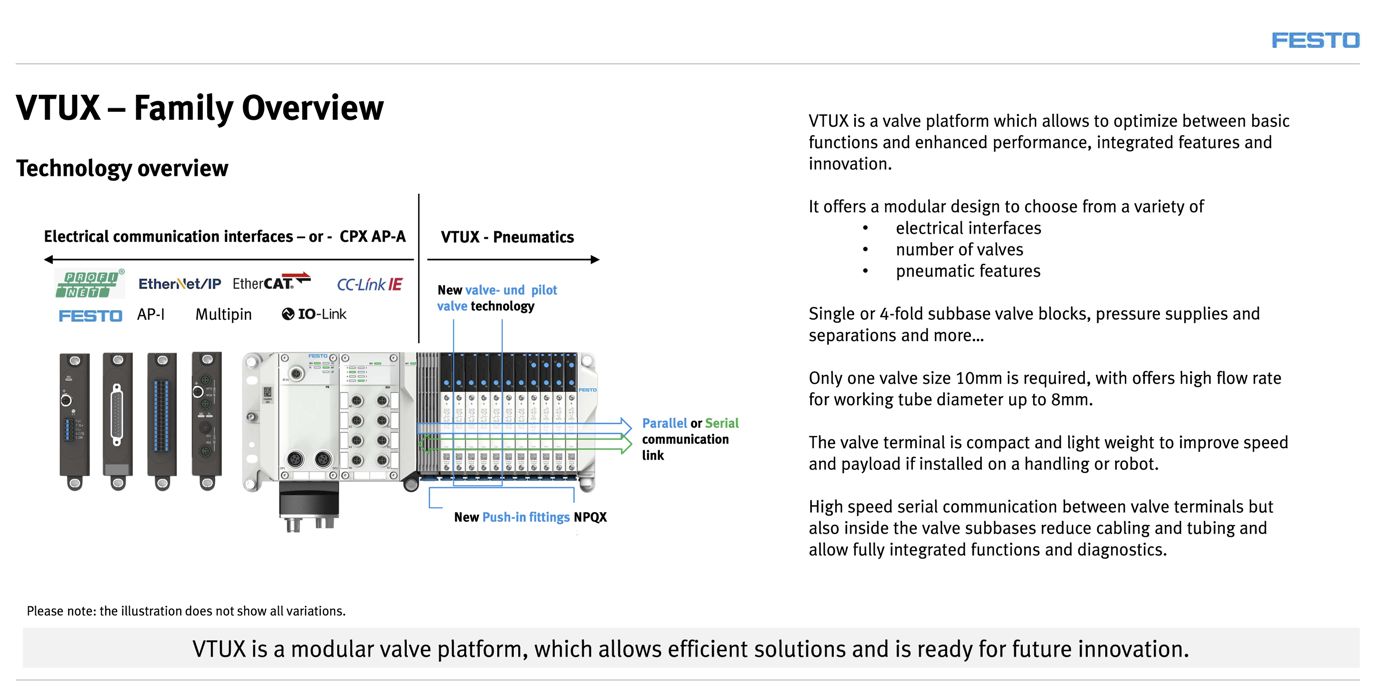

New | Festo Valve Terminal VTUX

New | Festo Valve Terminal VTUX

Configurable 670 L/per min on 10mm valve slice

Festo VTUX compact valve terminal - Based on a modular system, configured for hi-flow rates of up to 650 litres per minute on each valve slice. Fast delivery as a ready-to-install and fully tested configuration or for self-assembly from individual components.

Key features Control variants of the valve terminal VTUX The VTUX can be integrated in control systems in a variety of ways. There are a range of designs available for actuation via electrical multi-pin connection. Likewise, valve terminals can be connected via IO-Link® using round plugs with a high degree of protection or using terminal connections. The valve terminals are particularly versatile and high-performing thanks to the perfect integration into the Festo AP Automation Platform. In combination with the automation system CPXAP-A, valve terminals with various peripheral modules can be readily configured and assembled. Integration into the automation system CPX-AP-I offers numerous options, especially for decentralised solutions. It is thus possible to have particularly space-saving solutions close to the pneumatic drives, enabling rapid movements and short cycle times. Being able to combine the vale terminal with the automation system CPXAP-A as well as CPX-AP-I creates a unique solution for central and decentralised machine functions. This modularity makes the VTUX perfectly adaptable to any application.

Read more: New Festo Valve terminal VTUX - Compact with Hi-Performance